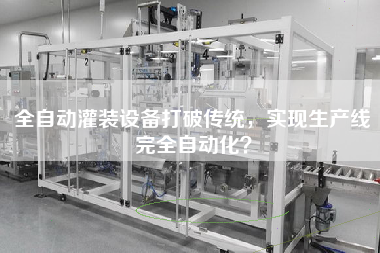

With the continuous development of science and technology, fully automatic production has become the trend of modern industry, and the emergence of fully automatic filling equipment makes the automation of the production line reach a new height. The emergence of automatic filling equipment not only improves the production efficiency, but also reduces the labor cost, and realizes the complete automation of the production line.

I. the concept of fully automatic filling equipment

Automatic filling equipment is a kind of fully automatic production equipment, which can fill all kinds of liquid, semi-liquid, viscous body and other substances into bottles or other containers according to certain proportion, speed, capacity and other requirements. The emergence of automatic filling equipment not only improves the accuracy and speed of filling, but also reduces the labor cost and improves the production efficiency.

Second, the advantages of automatic filling equipment

1. High efficiency

Automatic filling equipment can achieve high-speed and efficient filling operation, which can greatly improve production efficiency.

2. High precision

Automatic filling equipment can accurately control the filling capacity, can ensure that the filling volume of each bottle is consistent, so as to ensure the quality of the product.

3. Save manpower cost

Automatic filling equipment can realize automatic filling operation, which can reduce labor cost and improve production efficiency.

4. Reduce pollution

The fully automatic filling equipment can realize aseptic filling operation, reduce the secondary pollution of the product and improve the quality of the product.

Operation steps of fully automatic filling equipment

1. Preparatory work

Before using the fully automatic filling equipment, the equipment needs to be inspected and cleaned to ensure the normal operation of the equipment.

2. Equipment debugging

Before using the fully automatic filling equipment, the equipment needs to be debugged to ensure that the filling accuracy and speed of the equipment meet the requirements.

3. Filling operation

Put the material that needs to be filled into the hopper, start the equipment, and the equipment will automatically fill the material into the bottle.

4. Cleaning operation

After the filling is completed, the equipment needs to be cleaned to ensure the hygiene and cleanliness of the equipment.

Fourth, the application field of automatic filling equipment

Automatic filling equipment is widely used in food, medicine, cosmetics, daily chemical and other industries, which can realize the filling operation of all kinds of liquid, semi-liquid, viscous body and other substances.

V. Market prospect of fully automatic filling equipment

With the continuous popularization of fully automatic production, the market demand of fully automatic filling equipment is also increasing. In the future, automatic filling equipment will become an important part of production line automation and has a broad market prospect.

VI. Conclusion

The emergence of automatic filling equipment not only realizes the complete automation of the production line, improves the production efficiency, reduces the labor cost, but also ensures the quality of the product. In the future, fully automatic production will become the mainstream trend of the industry, and fully automatic filling equipment will also become an important part of production line automation.

YanMao palletizer

YanMao palletizer