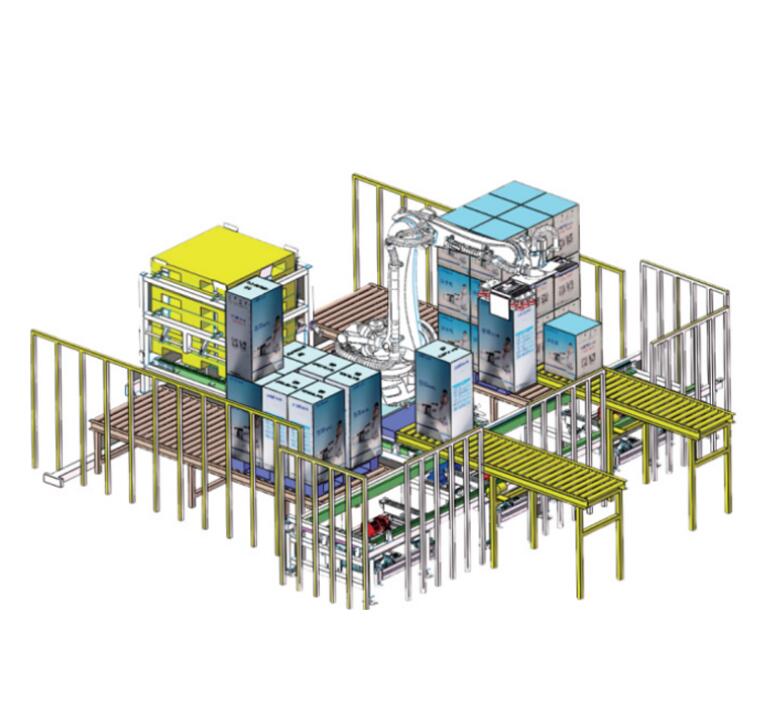

YanMao-P420 robot palletizing machine

Applications:

The robot palletizing machine is suitable for chemical, beverage, food, beer, plastics, air conditioning and other manufacturing companies to carry out boxing, bagging, canning, boxing, bottled and other forms of finished products for packing and palletizing.

Characteristics:

Picking bag, feeding bag, filling material, weighing in , sewing / sealing bag, bag-backwards and bag transmission are finished completely automatically.

Adopting PLC to guarantee the reliability of control

Adopting high-precision transducer and intelligent instrument to guarantee the accuracy and speed of weight

Adopting touch screen with trouble display and help system for easy operation.

Adopting imported pneumatic components features compact structure, reliable performance and convenient maintenance.

The sewing / sealing machine is an imported machine.

1, brand: YANMAO

2, carrying capacity: 20KG

3, stacking capacity of 200 to 400 boxes / hour

4, the number of axes: 4 axis

5, protection class IP67

6, palletizing form: according to customer requirements

7. The palletizing robot is a kind of specialized and integrated industrial equipment. The robot packs the packing boxes one by one in a pallet or box according to a predetermined grouping method. As a follow-up equipment for the packaging line, improving production capacity and transport capacity

8. The main material of the robot grip adopts aluminum alloy profiles, and the actuators adopt cylinders, which are characterized by light weight and flexible movement.

9, simple structure, high degree of specialization

10, low failure rate, reliable performance

11, maintenance and repair is simple, the required inventory of spare parts

12, small footprint, save space

13, simple operation, strong applicability

14. Flexible formation methods

15, this robot can simultaneously code different size specifications

| Type: | Packaging Line, Fully Automatic | Name: | Robot And Pallertizer Machine Lay Cartons Or Bags Onto The Pallets Or Put Something Into Some Place |

|---|---|---|---|

| Packing Material: | Plastic, Metal, Glass, Wood | Power Supply: | AC 380V 3 Phase |

| Laying Speed: | Carton Packing Speed 50-60cartons/min | Color: | Yellow/orange/white |

| Warranty: | 1 Year | Machine Test: | Provided |

High Light: |

Robot Palletizer Machine, plastic Robot Palletizer Machine, plastic robotic case palletizer |

||

YanMao palletizer

YanMao palletizer