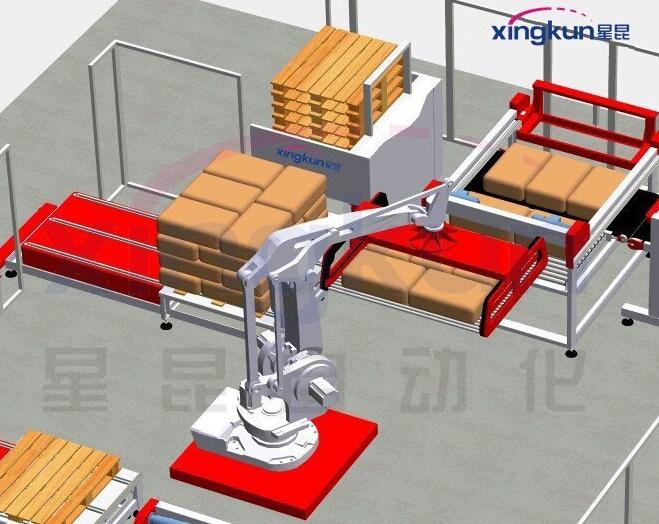

There is almost no industrial manufacturing field in the world where there is no need to stack the product. The task of stacking the box, bag, part or component to the tray is repeated, and many times is also dangerous. This is why many organizations seek automatic implementation of this process. What is better than the method of automated palletizing a robot? As an expert in robot palletizing and robot integration, this time we decide to share ten important aspects of the size of the size of the system:

1. The most important standard of palletizing robots: arrival / payload / speed / axis

Therefore, you have identified a potential robot palletizing application. Now you need to choose a robot suitable for this job. Each robot manufacturer offers a wide range of robotic specifications to meet customer needs. Standard points include:

reaching: The “arrival” of the robot is usually defined as the farthest distance from the robot center to the arm completely extended out of the arm. This is usually similar to the spherical shape, and the spherical shape must be considered when the product is stacked from a low height. The role of palletizing robots ranges from 70 to 125 inches. Payable: When choosing a suitable payload robot, multiple factors need to be considered. Remember that the payload includes both the weight of the arm end tool, including the product it is treated. You should also understand that the payload specified by the robot is valid for the focus on the center of the arm panel. Any offset on the arm end tool or product will reduce this overall payload.

Speed: It is difficult to classify and compare because the speed is typically represented by the rotational speed (ie / second) of each axis / joint. Usually, simulation needs to evaluate speed requirements.

Axis: The 4-axis robot is usually used because the products are often parallel to the floor when picking and placing in the palletizing application. A 5-axis or 6-axis robot can be used in the case where the product is required to rotate or til.

2. Other functions of palletizing robots

If you make simple search, you will definitely findThe application example of the palletizing application used in a variety of various industries. However, each application has its own unique aspects, making it different. There are also some other features to be applied to robot palletizing systems. Some of them may include:

Integrated or third-party robotic vision

forced feedback to pick up the case or part The measurement of

Enhanced safety software

Mobile robot / Rail robot system Mixed loading palletizing software

3. Palletizing robot repositions and Flexibility

“We don’t know what will be brought in the future,” This is a statement of packaging engineers or factory managers often talk about the future prospects of packaging. Since the habitual properties of consumer goods continue to change, today’s stacking may not be tomorrow. Robots are an excellent choice because a robot has great flexibility in dealing with various products and patterns. If the future product specifications are known in advance, you can choose the appropriate robot and you can design the arm end tool in a easy and easily change. In the case of complete unique requirements, robotics can reuse the same robot multiple times, while only replacing tools or auxiliary equipment, can still fall to the lowest implementation requirements.

4. Palletizing robot reduces maintenance cost

Prior to the emergence of robots, the traditional palletircraft ruled the entire industry. These systems use conveyors, steering mechanisms, pushers, stacked stages, detachment plates, and lifts to form a product layer to be stacked. These systems are effective, but they usually contain a large number of active components and preventive maintenance components. The robot is basically a set of cast iron arms and servo motors, which requires rare, and will become one of the most reliable equipment in your facility. 5. The design of the pallet machine arm tool design

The core of any robot system is the end tool of the arm. The arm end tool is the last thing to touch the customer product before the customer receives the product. This means that it is critical to the successful robot palletizing system, gentle, reliable, effectively handled boxes, bags or parts. The end of the robot palletizer can take the following form:

Partition vacuum cup block without a bottom support General vacuum suction cup clamshell grip

If you have code Demand, please contact our palletizing machine expert and determine if the automatic palletizing system can help you achieve business goals.

YanMao palletizer

YanMao palletizer