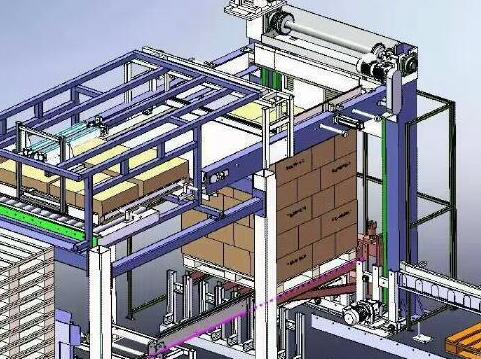

The formal maintenance of palletizing robots is very important Smart robot work is much more efficient than human resources, Emphasize that the maintenance of palletizing robots must be recorded and on time.

We must do a good job in the status of palletizing robots in the usual situation, which can immediately grasp the trend and condition of machinery equipment, and must pay attention to it in the case of maintaining maintenance. A lot of data information.

1, do a good job in the record and archiving of the maintenance and maintenance of the pallet, normatively, formalized the content of the new project of technical maintenance. The maintenance standards for pallet machine machine equipment refers to technical maintenance technologies for mechanical equipment. Standard requirements. All pallet machine machine equipment has long been clearly proposed, the maintenance of the daily maintenance and on-time maintenance of the machine equipment has long, and the maintenance can make equipment

2, everyone Be sure is based on the content and regulations of the new projects, and the relative technical maintenance form is easy to carry out maintenance and record, but also established a complete machinery and equipment archive information, which will post the maintenance and resolving the mechanical equipment and its maintenance According to.

The professional and technical personnel of Suzhou Tao’s intelligent equipment pay attention to the maintenance record of the palletizing robot, which is very important, and everyone can master the details of the intelligent robot in future applications. It is convenient for the production and processing of common faults.

How to deal with The presence of the palletizing robot, the presence of the palletizing robot has been very large. Assist, how is the common fault of palletizing robots to handle?

1, air leakage air leakage: cut off the valve ring or the power switch ring. Replace the ring.

2, exhaust pipe leakage: cutting off the valve ring or the power switch ring damage or the engine piston is damaged. Replace the ring.

3, the hydraulic cylinder leakage: the bottom end ring of the behavior body. The ring should be replaced at this time.

4, the palletizing robot clamping posture is slow or the clamping stroke is not enough: the footBollens are loose, front buckle or automatic pipe trap damage. At this time, the ground bolt can be tightened, pay attention to the appropriate part of the front buckle axis. You can also replace the front buckle or fully automatic pipe. According to the above manner, the common faults of palletizing robots can be handled, and we hope to assist you, the Tempera Chaletau Plant.

YanMao palletizer

YanMao palletizer