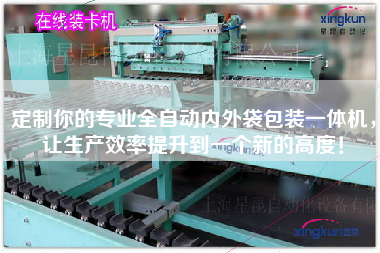

Customize your professional fully automatic inner and outer bag packaging all-in-one machine, so that the production efficiency to a new height!

In modern industrial production, automatic production has become a trend. In the packaging industry, professional automatic internal and external bag packaging machine has become an indispensable equipment. In order to meet the different needs of enterprises, customized professional fully automatic inner and outer bag packaging all-in-one machine has become a common choice. In this article, we will introduce how to customize the professional fully automatic inner and outer bag packaging machine to raise the production efficiency to a new level.

First, understand the professional fully automatic integrated machine for inner and outer bag packaging

Before we begin to customize the professional fully automatic inner and outer bag packaging all-in-one machine, we need to know the basic knowledge of this equipment. Professional automatic inner and outer bag packing all-in-one machine is a kind of equipment which can complete inner bag and outer bag packing. it can automatically complete many steps such as bag making, filling, sealing, coding, counting and so on. This kind of equipment can greatly improve production efficiency, save labor costs, and ensure the quality and hygiene of packaging at the same time.

Second, choose the right manufacturer

Before customizing professional fully automatic inner and outer bag packaging all-in-one machine, we need to choose a suitable manufacturer. Choosing the right manufacturer can ensure the quality of the equipment and after-sales service. When choosing a manufacturer, we need to consider the following aspects:

1. The qualification and reputation of manufacturers: we need to choose qualified manufacturers, but also need to understand the reputation and reputation of manufacturers.

two。 The quality of equipment: the quality of equipment is an important consideration for us to choose manufacturers, we need to choose guaranteed equipment.

3. After-sales service: after-sales service is another important consideration for us to choose manufacturers, we need to choose manufacturers that provide perfect after-sales service.

Third, determine customized requirements

After selecting the right manufacturer, we need to determine the customization requirements. When determining custom requirements, we need to consider the following aspects:

1. Types and specifications of packaging materials: we need to determine the type and parameters of the equipment according to the types and specifications of packaging materials.

two。 Packing speed: packing speed is an important consideration in the selection of equipment, we need to determine the packing speed according to the production demand.

3. Packing form: we need to determine the form of packing, inner bag packing or outer bag packing, or inner and outer bag packing.

4. Other requirements: we also need to consider other requirements, such as coding, counting, filling, etc.

Customized professional fully automatic integrated machine for inner and outer bag packaging

After determining the customization requirements, we can begin to customize professional fully automatic inner and outer bag packaging all-in-one machine. In the customization process, we need to communicate with manufacturers to tell them our needs and requirements. In the customization process, we need to pay attention to the following aspects:

1. Model and parameters of the equipment: we need to determine the type and parameters of the equipment according to the types and specifications of the packaging materials.

two。 Structure and function of the equipment: we need to determine the structure and function of the equipment according to the packaging requirements.

3. Equipment configuration and options: we need to determine the equipment configuration and options according to production requirements.

4. Price and delivery time of the equipment: we need to negotiate the price and delivery time of the equipment with the manufacturer.

V. use and maintenance

After customizing the professional fully automatic inner and outer bag packaging all-in-one machine, we need to use and maintain it. In the process of use, we need to pay attention to the following aspects:

1. Operating rules: we need to use the equipment in accordance with the operating rules to avoid damage to the equipment caused by improper operation.

two。 Maintenance: we need to maintain the equipment regularly to ensure the normal operation of the equipment.

3. Safety precautions: we need to pay attention to the safe use of the equipment to avoid accidents.

Summary

Customized professional fully automatic inner and outer bag packaging all-in-one machine can greatly improve production efficiency, save labor costs, and ensure the quality and hygiene of packaging. In the customization process, we need to select the appropriate manufacturer, determine the customization requirements, and pay attention to the operation and maintenance of the equipment. Only in this way can we raise our production efficiency to a new level.

YanMao palletizer

YanMao palletizer