With the continuous improvement of the degree of production automation, more and more enterprises begin to pay attention to the introduction and application of automation equipment. Among them, fast automatic packing equipment, as an efficient production automation equipment, has been favored by more and more enterprises. So, what on earth is a fast automatic boxing device? What are its advantages? How to use it correctly? This article will answer for you one by one.

What is the fast automatic packing equipment?

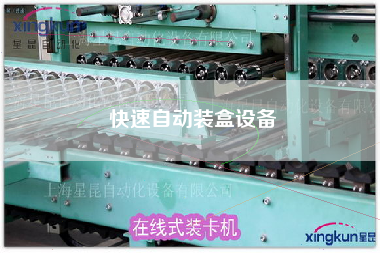

Fast automatic packing equipment is a kind of automatic packing equipment, which can automatically load the product into the box and complete the operation of sealing, coding and so on. Compared with the traditional manual packing method, the fast automatic packing equipment has the advantages of high efficiency, low cost, simple operation and so on.

Second, the advantages of fast automatic packing equipment

1. Improve production efficiency

Fast automatic packing equipment can realize continuous automatic packing, which greatly improves the production efficiency. Compared with the traditional manual packing method, the efficiency of fast automatic packing equipment can be increased by more than 10 times.

two。 Reduce production cost

Fast automatic packing equipment can reduce labor input and production cost. At the same time, it can also reduce the loss of products and the waste of packaging materials, and further reduce production costs.

3. Improve the quality of products

The fast automatic packing equipment can improve the accuracy and consistency of packing and avoid the errors and differences in manual packing. This can ensure the quality and consistency of the product.

4. Easy to operate

The operation of the fast automatic packing equipment is very simple, and it only takes a few people to complete the whole packing process. This can reduce manpower input and training costs.

Third, how to use the fast automatic packing equipment correctly?

1. Preparatory work

Some preparatory work needs to be done before using fast automatic boxing equipment. First of all, it is necessary to check whether the equipment is running normally, and whether the power supply, transmission system, control system and so on are normal. Secondly, the equipment needs to be cleaned and maintained to ensure the hygiene and normal operation of the equipment.

two。 Debugging equipment

Before using the fast automatic packing equipment, the equipment needs to be debugged. First of all, the transmission system and control system of the equipment need to be debugged to ensure that the equipment can operate normally. Secondly, the parameters of the equipment need to be adjusted according to the size and weight of the product.

3. Operating equipment

When using fast automatic packing equipment, you need to follow the operating procedures. First of all, you need to place the product at the feed port of the equipment, and then start the equipment. The equipment will automatically load the product into the box, and complete the sealing, coding and other operations. Finally, the packed box needs to be taken out of the equipment and placed in the specified location.

IV. Summary

Fast automatic packing equipment is a kind of efficient production automation equipment, which can improve production efficiency, reduce production cost and improve product quality. When using fast automatic packing equipment, it is necessary to prepare, debug the equipment and operate in accordance with the operating procedures. Only by using the fast automatic packing equipment correctly can it give full play to its maximum benefit.

YanMao palletizer

YanMao palletizer