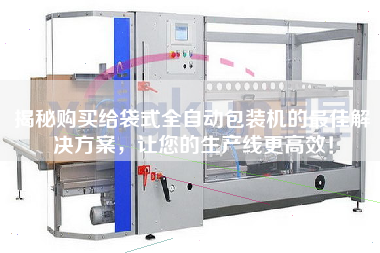

Reveal the best solution to buy for bag automatic packaging machine to make your production line more efficient!

Key words: buy the solution of bag-type automatic packaging machine

In modern industrial production, automation equipment is more and more widely used, in which the bag-type automatic packaging machine is an indispensable part. It is the pursuit of every enterprise to buy an efficient, stable and easy-to-operate bag-type automatic packaging machine, but in the market, various brands, models, prices and performance packaging machines are dazzling and dazzling. How to choose the best solution? This article will reveal the best solution to buy to the bag automatic packaging machine to make your production line more efficient!

First, understand the basic principle and function of the full-automatic packaging machine.

The bag-type automatic packaging machine is a kind of automatic packaging equipment which integrates many functions such as bag making, measuring, filling, sealing, cutting, counting, printing batch number and so on. Its working principle is: send the bag made by the bag-making mechanism to the filling mechanism, fill the material automatically through the metering device, and then seal the bag, cut off, count, print the batch number and so on. The advantages of automatic bag packing machine are: high efficiency, stability, reliability, simple operation and easy maintenance.

Second, the key factors of selecting automatic bag packing machine.

1. Product properties: different product properties have different requirements for packaging machines, such as powder, granular, liquid, paste and other products need to choose different packaging machine models.

two。 Packaging bag material: different packaging bag materials have different requirements for the packaging machine, such as paper bags, plastic bags, aluminum foil bags and so on.

3. Bag size: different bag sizes have different requirements for the packaging machine, so different packaging machine models need to be selected according to the actual situation.

4. Packaging speed: different packaging speeds have different requirements for packaging machines, and different packaging machine models need to be selected according to the actual production needs.

5. Packaging accuracy: different packaging accuracy has different requirements for packaging machines, so different models of packaging machines need to be selected according to the actual production needs.

6. Price: the price of packaging machine varies greatly with different brands, models, configuration and performance, so we need to choose the best solution according to the actual production demand and budget.

Third, buy the best solution for the bag-type automatic packaging machine

1. Choose well-known brands: choose well-known brand packaging machine, the quality is guaranteed, after-sales service is more assured.

two。 Choose your own model: choose your own model according to the actual production needs, do not blindly pursue high-end models.

3. Choose the configuration that suits you: choose the configuration that suits you according to the actual production needs, and don’t blindly pursue high configuration.

4. Choose the price that suits you: choose the price that suits you according to the actual production demand and budget, and don’t blindly pursue low prices.

5. Choose a reliable supplier: choose a reliable supplier, the after-sales service is more assured and more secure.

Fourth, the operation steps of the bag-feeding automatic packaging machine

1. Preparation: check whether the packaging machine and its surrounding environment are clean and hygienic, and check whether the packaging materials meet the requirements.

two。 Boot operation: operate according to the instructions of the packaging machine, put the packaging material into the packaging machine, and start up and run.

3. Debugging operation: debug the packaging machine according to the instructions to ensure the normal operation of the packaging machine.

4. Production operation: put the materials to be packed into the packaging machine, operate according to the instructions of the packaging machine, and complete the packaging production.

5. Cleaning operation: after the end of packaging production, clean the packaging machine and the surrounding environment to ensure that the environment is clean and hygienic before the next production.

V. Summary

The purchase of bag-type automatic packaging machine is an important means to improve production efficiency, and the selection of the best solution is the key. Understand the basic principles and functions of the packaging machine, select the key factors, choose the best solution, master the operation steps, in order to make the production line more efficient. I hope this article can provide some reference and help for you when buying for the bag-type automatic packaging machine.

YanMao palletizer

YanMao palletizer