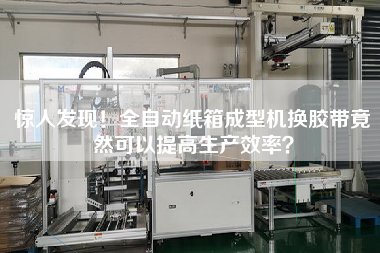

Automatic carton forming machine is one of the indispensable equipment in modern logistics industry. it can automatically complete the folding, bonding and cutting of cartons, which greatly improves the production efficiency and production quality. However, due to the long-term use and the aging of the tape, the bonding effect of the carton molding machine will gradually become worse, resulting in problems in the production process. In order to solve this problem, we usually choose to change the tape, but, you know what? Full-automatic carton molding machine to change tape can actually improve production efficiency!

Next, I will introduce to you the correct method and matters needing attention to change the tape of the automatic carton molding machine.

I. preparatory work

We need to do some preparatory work before changing the tape. First of all, it is necessary to turn off the power of the carton molding machine and remove the blade of the tape cutter to avoid damaging the blade when replacing the tape. Second, new tape and blades for tape cutters need to be prepared.

Second, replace the tape

1. Open the tape box of the carton molding machine, remove the original tape, and clean up the dust and debris in the tape box.

two。 Remove the new tape from the tape box and stick it on the tape box according to the direction and position of the original tape.

3. Pull the tape out for a while, then put it into the tape transfer system of the carton molding machine, and secure the tape to the blade of the tape cutter.

4. Turn on the power of the carton molding machine and carry out a trial operation to ensure that the adhesive tape has a good bonding effect.

Matters needing attention

1. When replacing the tape, it is necessary to pay attention to the specification and quality of the tape. Selecting a suitable tape can greatly improve the production efficiency and quality.

two。 When changing the tape, it is necessary to carefully clean the tape box and tape delivery system to avoid dust and sundries affecting the bonding effect of the tape.

3. When replacing the tape, it is necessary to turn off the power of the carton molding machine and remove the blade of the tape cutter to avoid damaging the blade when replacing the tape.

4. After replacing the tape, it is necessary to carry out a trial run to ensure that the tape has a good bonding effect.

In a word, although it seems simple to change the tape of the automatic carton molding machine, the correct operation method and matters needing attention are very important. Only by mastering the correct operation method, can we ensure the improvement of production efficiency and production quality.

YanMao palletizer

YanMao palletizer